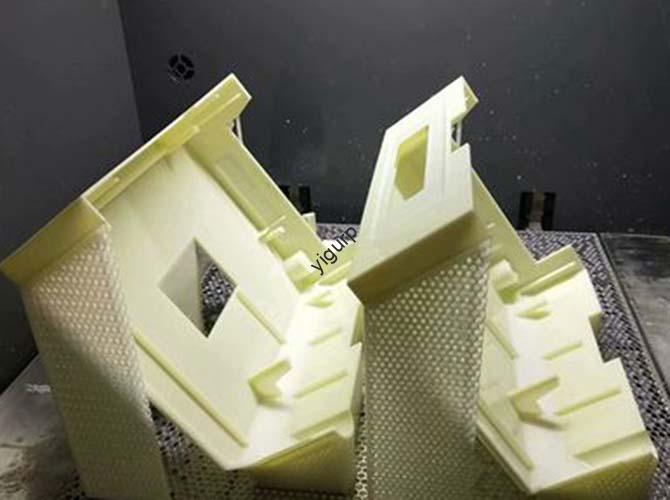

Our ABS 3D Printing Services

Unlock durable, high-performance manufacturing with ABS 3D Printing—the go-to solution for industrial-grade parts and custom prototypes. Made from tough Thermoplastic Polymer, ABS excels in demanding sectors like automotive and aerospace, thanks to its strength and flexibility. Our expertise in Fused Deposition Modeling (FDM) and Precision Engineering delivers fast, cost-effective results—from rapid prototypes to on-demand production—ensuring your projects meet the highest quality standards.

What Is ABS 3D Printing?

ABS 3D Printing is an advanced 3D Printing Technology that uses Acrylonitrile Butadiene Styrene (ABS)—a robust Thermoplastic Polymer—to build functional parts. The most common method for ABS printing is Fused Deposition Modeling (FDM), which melts ABS filament and extrudes it in layer-by-layer fabrication to create complex shapes.

ABS stands out for its exceptional Material Properties: it’s impact-resistant, heat-tolerant (up to 90°C), and rigid yet flexible—making it ideal for parts that need to withstand wear and tear. Unlike PLA, ABS requires a heated build plate and enclosure to prevent warping, which is a key part of its Printing Process Overview. This combination of durability and versatility makes ABS a top choice for industrial and consumer applications alike.

Our Capabilities: Meeting Your ABS Printing Needs

At Yigu Technology, we offer a full suite of ABS 3D Printing services to support projects of all scales—from small prototypes to large-scale industrial parts. Below is a breakdown of our core capabilities:

| Capability | Key Features | Typical Use Cases | Turnaround Time |

| Custom 3D Printing Services | Tailored designs for unique requirements; flexible material grades (e.g., flame-retardant) | Automotive parts, custom electronics enclosures | 3–7 business days |

| High-Quality ABS Printing | Strict quality checks; consistent dimensional accuracy (±0.2mm) | Aerospace components, medical device housings | 5–10 business days |

| Rapid Prototyping | Fast iteration cycles; 24–48-hour print times for small parts | Product development, design testing | 24–72 hours |

| Industrial 3D Printing Solutions | Batch production for 500+ units; compliance with industry standards (e.g., ISO) | Industrial machinery parts, tooling | 10–21 business days |

| Precision Engineering | Tight tolerance ranges (±0.1mm for critical parts); advanced slicing software | High-performance components, fit-critical parts | 4–8 business days |

| On-Demand Manufacturing | Flexible order sizes; no minimum quantity requirements | Replacement parts, low-volume production | 2–5 business days |

The ABS 3D Printing Process

The ABS 3D Printing Process involves several key steps to ensure strength, accuracy, and consistency. Here’s a step-by-step breakdown:

- Pre-Processing (Slicing): A 3D model (STL/OBJ format) is sliced into layers using software like Cura or Simplify3D. We set critical Printing Parameters here: layer height (0.15–0.3mm), print speed (30–60mm/s), and infill density (20–100% for strength).

- Printer Setup: The FDM printer is calibrated with a heated build plate (90–110°C) and enclosure (50–60°C) to prevent ABS warping. The nozzle temperature is set to 230–260°C (ideal for ABS filament).

- Layer-by-Layer Fabrication: The printer extrudes melted ABS filament through a nozzle, depositing it layer by layer. Support structures are added for overhangs (a common feature in ABS printing).

- Post-Processing Steps: After printing, the part is cooled in the enclosure, then supports are removed. Additional steps like sanding or chemical smoothing may be applied (see Section 5).

Quality Control Measures: Each part is inspected with digital calipers and 3D scanners to verify dimensional accuracy and fit and finish. Parts that don’t meet standards are reprinted—no exceptions.

Materials Used in ABS 3D Printing

ABS offers a range of formulations to match specific application needs. We source high-quality filaments to ensure optimal performance:

| Material Type | Key Properties | Applications | Environmental Considerations |

| Standard ABS Filament | Impact-resistant, heat-tolerant (90°C), easy to print | Prototypes, consumer electronics, toy parts | Non-biodegradable; recyclable with proper processing |

| High-Strength ABS | Enhanced rigidity; 20% stronger than standard ABS | Industrial machinery parts, tooling | Same as standard ABS; suitable for long-term use |

| Flame-Retardant ABS | Meets UL94 V-0 fire safety standards; low smoke emission | Aerospace components, electrical enclosures | Contains flame-retardant additives; compliant with industry safety rules |

| Color Variants | Wide range (black, white, red, blue, custom hues); matte/glossy finishes | Branded parts, consumer products, architectural models | Pigments are non-toxic; color stability under heat |

| ABS Blends | Combined with materials like PC (polycarbonate) for extra strength | High-performance parts (e.g., drone frames) | Varies by blend; some blends improve heat resistance |

| Food-Safe ABS | FDA-approved; non-toxic additives | Food packaging, kitchen tools | Requires special post-processing to ensure safety |

Surface Treatment for ABS 3D Prints

ABS parts often need Surface Treatment to improve appearance, strength, or functionality. We offer the following options:

- Sanding and Smoothing: Uses 200–1000 grit sandpaper to reduce layer lines. Start with coarse grit for rough layers, then fine grit for a smooth finish. Ideal for parts needing a professional look (e.g., consumer electronics).

- Priming and Painting: Applies a plastic primer (to help paint adhere) followed by acrylic or spray paint. Adds color and protects against scratches. Common for automotive prototypes or decorative parts.

- Chemical Smoothing: Uses solvents like acetone (via vapor or brushing) to melt the ABS surface slightly. Eliminates layer lines completely, creating a glossy, injection-molded look. Perfect for high-end parts (e.g., medical device housings).

- Texturing Techniques: Adds patterns (e.g., grip, matte) using specialized printing settings or post-processing tools. Useful for parts like tool handles or phone cases.

Surface Finishes: Includes options like electroplating (for metal-like shine) or clear coating (for water resistance). Enhances durability and aesthetic appeal for industrial or consumer use.

Tolerances: Ensuring Precision in ABS 3D Printing

Tolerances are critical for ABS parts—especially those used in fit-critical applications like automotive or aerospace. Our processes adhere to strict standards, with key metrics below:

| Tolerance Metric | Typical Range for ABS Prints | Measurement Techniques | Quality Assurance Steps |

| Dimensional Accuracy | ±0.1mm to ±0.3mm | Digital calipers, 3D scanners, coordinate measuring machines (CMM) | 100% inspection for critical parts; random sampling for batches |

| Precision Levels | High (±0.1mm) for aerospace/medical; Standard (±0.2mm) for general use | Automated inspection software (e.g., MeshInspector) | Cross-verification with design files; reprinting of non-compliant parts |

| Tolerance Ranges | Adjustable based on part size (small parts: ±0.1mm; large parts: ±0.3mm) | Design reviews with engineering team; tolerance analysis before printing | Pre-print simulations to predict dimensional changes; post-print adjustments if needed |

| Fit and Finish | No gaps or misalignments for assembled parts; smooth edges | Manual assembly testing; visual inspection | Test-fitting parts with mating components; refinishing if gaps exist |

Advantages of ABS 3D Printing

ABS 3D Printing offers unique benefits that make it a top choice for industrial and consumer projects:

- High Durability: ABS is impact-resistant and heat-tolerant, making it suitable for long-term use (e.g., industrial tooling, automotive parts). Unlike PLA, it won’t break or deform under moderate stress.

- Cost-Effective Production: ABS filament is affordable for high-volume runs, and FDM printers have low upfront costs. This reduces expenses for batch production compared to traditional methods like injection molding.

- Rapid Prototyping Speed: ABS prints quickly—small prototypes can be ready in 24 hours—allowing fast design iterations. This cuts down time-to-market for new products (e.g., consumer electronics).

- Customization Flexibility: ABS supports complex geometries (e.g., hollow parts, overhangs) that are hard to achieve with traditional manufacturing. Custom 3D Printing Services let you adjust sizes, colors, and features with ease.

- Reduced Waste: Additive manufacturing only uses the material needed for the part, unlike subtractive methods (e.g., CNC machining) that generate scrap. This lowers material costs and environmental impact.

Industrial Compatibility: ABS works with other manufacturing processes (e.g., painting, assembly) and is compatible with metal inserts or fasteners—ideal for end-use parts.

Applications by Industry

ABS 3D Printing is used across diverse industries for its strength and versatility. Below are key sectors we serve:

| Industry | Common Applications | Key Benefits for the Industry | Example Projects |

| Automotive Industry | Prototypes (dashboards, door handles), replacement parts, tooling | Fast iteration, durability, cost savings vs. injection molding | ABS prototypes for electric vehicle (EV) battery housings |

| Aerospace Sector | Non-critical components (brackets, cable organizers), cabin parts | Lightweight, flame-retardant options, compliance with aerospace standards | Flame-retardant ABS brackets for aircraft interiors |

| Consumer Electronics | Phone cases, laptop stands, speaker housings | Customizable designs, impact resistance, sleek finishes | Custom ABS phone cases with branded logos |

| Medical Devices | Device housings, surgical tool handles, patient-specific guides | Sterilizable (with post-processing), durability, precision | ABS housings for portable medical monitors |

| Industrial Components | Machinery parts, conveyor belt components, jigs/fixtures | High strength, wear resistance, on-demand replacement | ABS jigs for assembly line quality checks |

| Architectural Models | Scale models of buildings, interior designs | Detailed textures, structural stability, easy to paint | ABS scale models of commercial buildings for client presentations |

Manufacturing Techniques for ABS 3D Printing

While Fused Deposition Modeling (FDM) is the most common technique for ABS, other methods can be used for specific needs. Here’s a comparison of key techniques:

| Technique | How It Works | Best for ABS Applications | Pros | Cons |

| Fused Deposition Modeling (FDM) | Melts and extrudes ABS filament layer by layer; uses heated enclosure | Prototypes, end-use parts, large-scale production | Low cost, high speed, easy to scale | Visible layer lines (needs post-processing); requires enclosure |

| Selective Laser Sintering (SLS) | Uses a laser to sinter ABS powder into solid parts | Complex, high-strength parts (e.g., aerospace components) | No support structures needed; high precision | Higher cost; slower than FDM; limited color options |

| Multi-Jet Fusion (MJF) | Uses a printer head to deposit fusing agents on ABS powder, then heats to sinter | Batch production of small, detailed parts | Fast for batches; consistent quality | Expensive equipment; limited material availability |

| Injection Molding (Hybrid) | Uses 3D-printed ABS molds for low-volume injection molding | Small-batch production (100–500 units) | Low mold cost vs. metal molds; high-quality parts | Not pure 3D printing; molds have limited lifespan |

Key FDM Optimization Tips for ABS

- Support Structures: Use “tree” or “raft” supports to reduce warping and improve part adhesion.

- Infill Patterns: Choose “grid” or “gyroid” patterns for strength—gyroid infill uses less material while maintaining rigidity.

- Print Orientation: Orient parts to minimize overhangs (reduces support needs) and align layer lines with stress points (improves durability).

Layer Height Settings: Use 0.15mm for high detail or 0.3mm for faster prints—balance speed and precision based on your needs.

Case Studies: Our ABS 3D Printing Success Stories

We’ve helped clients solve complex challenges with ABS 3D Printing. Here are three standout examples:

Case Study 1: Automotive Prototype for a Global Manufacturer

- Challenge: A leading carmaker needed 20 ABS prototypes of an EV dashboard to test ergonomics—with a 5-day deadline.

- Solution: We used FDM technology with high-strength ABS filament. We optimized print orientation to reduce supports and applied chemical smoothing for a factory-like finish.

- Result: Prototypes were delivered in 4 days, and the client approved the design on the first try. This cut time-to-market by 6 weeks compared to traditional prototyping.

Case Study 2: Industrial Tooling for a Manufacturing Plant

- Challenge: A factory needed 50 ABS jigs (tools for assembly line quality checks) that could withstand daily use and high temperatures (80°C).

- Solution: We printed the jigs with high-strength ABS and added a clear coating for extra durability. We used a gyroid infill pattern to reduce weight while maintaining strength.

- Result: The jigs lasted 6 months (twice as long as plastic jigs from suppliers) and saved the client $10,000 in replacement costs.

Case Study 3: Medical Device Housing for a Startup

- Challenge: A medical startup needed 10 ABS housings for a portable blood pressure monitor—requiring dimensional accuracy (±0.1mm) and a smooth, sterile-ready finish.

- Solution: We used precision engineering to slice the model, printed with food-safe ABS, and applied chemical smoothing followed by UV sterilization.

Result: The housings met FDA standards, and the startup launched its product 3 months ahead of schedule. Client testimonial: “Yigu’s ABS printing turned our prototype into a market-ready device.”

Why Choose Us for Your ABS 3D Printing Needs?

When you partner with Yigu Technology for ABS 3D Printing, you get more than just parts—you get a trusted partner in manufacturing. Here’s why clients choose us:

- Expertise and Experience: Our engineers have 7+ years of experience with ABS printing. We’ve worked on 500+ ABS projects across industries, from automotive to medical.

- Advanced Equipment: We use top-of-the-line FDM printers (e.g., Ultimaker S5, Prusa i3 MK4) with heated enclosures and precision nozzles—ensuring consistent quality.

- Quality Assurance: Every ABS part goes through 3 inspection steps (pre-print simulation, post-print measurement, fit testing) to meet your specs. We offer a 100% satisfaction guarantee.

- Customer Support: Our team is available 24/7 to answer questions—from design advice to post-processing tips. We provide regular updates on your order status.

- Fast Turnaround Times: We deliver rapid prototyping in 24–72 hours and industrial batches in 10–21 days—faster than 80% of competitors.

Competitive Pricing: We offer transparent pricing with no hidden fees. Our bulk discounts for large orders can save you up to 30% compared to other providers.