About Yigu Rapid Prototype

Yigu Rapid Prototype was established in 2021 and is located in Dongguan. We are ISO 9001:2015 certified. We are committed to providing manufacturing solutions for your innovative ideas and products, offering one-stop services from prototyping to production.

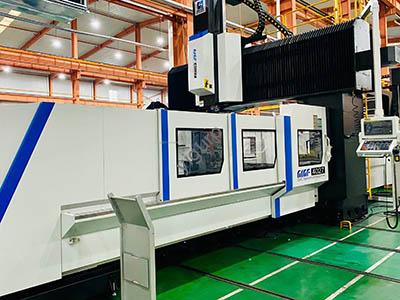

Yigu’s manufacturing facilities span 5,000 square meters and employ over 190 staff members, including 30 highly skilled technicians. We also operate over 50 CNC machines, including 3-axis, 4-axis, and 5-axis machines.

Additionally, we offer drilling, tapping, EDM (electrical discharge machining), planar grinding, and wire cutting services for your parts. With our robust capabilities, we can flexibly produce your parts quickly and to the highest quality standards.

CNC machining workshop equipment

3D Printing workshop equipment

Company Mission and Vision

The company’s mission and vision include the following three aspects

Our service scope

1. Various processing techniques: CNC machining, silicone molding, sheet metal processing, low-pressure casting.

2. Surface treatment: painting, anodizing, sandblasting, electroplating, mirror finishing, heat treatment, etc.

3. Rapid delivery: Quick quotes within hours, with parts manufactured in as little as 4 days.

4. Strict quality control: We have introduced advanced international equipment such as 2D and 3D measuring instruments, calipers, micrometers, height gauges, pin gauges, and height meters for inspection.

Why choose us?

Yigu Rapid Prototype is a large-scale prototype and rapid manufacturing company with advanced expertise in prototyping, CNC machining, silicone molding, sheet metal processing, and low-pressure casting. We offer our customers one-stop services ranging from customized product samples to small-batch production, and we can also provide personalized services to meet the needs of our customers at every stage. With our strong production capabilities, we can flexibly arrange production cycles to meet your various product production needs.

- Solution Provider: One-stop service from prototyping to mass production, helping customers succeed and achieve future technological innovation;

- Professional Team: Strong manufacturing capabilities, prototype model production in 2-10 days, rapid production in 2-5 weeks;

- Strict Quality Control: Quality you can trust, ISO 9001:2015 quality certified, experienced engineers, and comprehensive production and testing equipment;

- Extensive Industry Experience: Manufacturing advantages, years of technical expertise, and extensive industry experience, with a monthly production capacity of 10,000 units and service to over 5,000 development projects;

- High-Standard Confidentiality Principles: Strict confidentiality measures, long-term awareness of confidentiality risks, and a commitment to ensuring the security of client product information.

SNS: Linkedin, Facebook, Instagram, Twitter, Youtube, Tiktok.