Industrial Rapid Prototype Solution

Yigu has over 15 years of experience in rapid prototyping services, helping customers with the entire process from concept to actual product, providing comprehensive solutions to ensure product quality, functionality, and delivery time.

- Shell and appearance parts (overall shape customization and surface treatment)

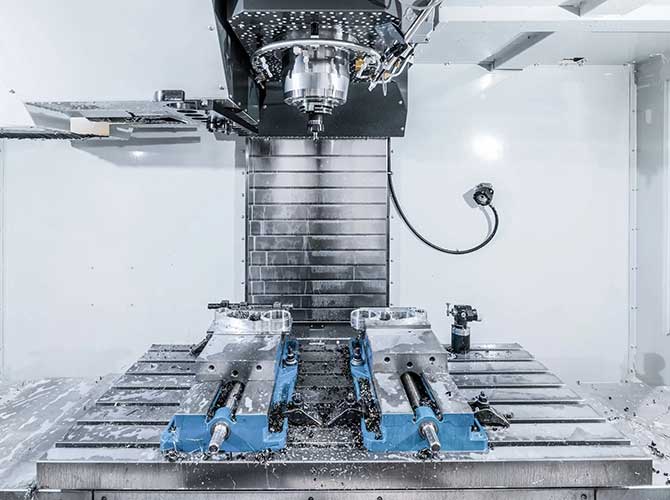

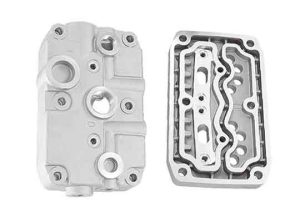

- Structural parts (5-axis CNC machining and precision up to 0.01mm)

- Small-batch production (CNC machining, 3D printing, low-pressure injection and silicone mold making,

One stop custom rapid prototype to small batch manufacturing solution provider

Yigu has obtained ISO 9001:2015 quality certification and has over 15 years of experience in the prototype industry. We have strong production capabilities and can flexibly arrange production cycles to meet your production needs.

Prototype custom

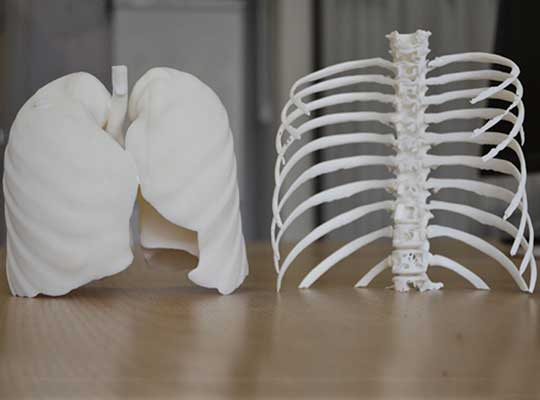

We provide a wide range of prototype technology for customized finished products such as appearance prototypes and structural prototypes, utilizing CNC machining, 3D printing, sheet metal processing, and various post-processing techniques to provide customers with highly customized prototypes. These prototypes not only enable quick validation of design concepts and product functionality, but also help identify potential design issues in the early stages. Prototype customization services help customers reduce development risks, improve product quality, and accelerate product launch speed. Flexible material selection, precise processing technology, and personalized service make prototype customization an ideal choice for innovation and optimized design. Prototype can be applied to various industries, including automotive, medical equipment, and consumer electronics, to achieve faster innovation and cost-effective product development, meeting the specific needs of your project.

Small batch production

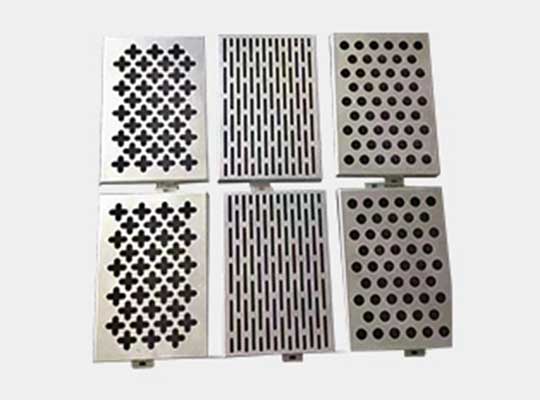

Small batch production is usually used in the trial production stage after prototype validation testing. Compared to large-scale production, small batch production has the advantages of flexibility and customization. By adopting small batch manufacturing technologies such as CNC machining, silicone replication, RIM low-pressure infusion, sheet metal processing, and precision machining of parts, small batch production can achieve efficient and accurate production while reducing inventory pressure and production costs. This model enables enterprises to respond more quickly to changes in market demand, launch new products, and gain a competitive advantage in a fiercely competitive market. Small batch production also provides convenience for customized products and meets personalized needs. This flexible production method helps to reduce initial investment and minimize resource waste, making it an ideal choice for adapting to rapid development and changing markets.

Custom prototype to small-scale production process

Batch Manufacturing production process

Rapid prototype product cases

Batch Manufacturing part cases

Complete your prototype custom in 5 steps

About Yigu Rapid Prototype

We provide a comprehensive solution for prototype manufacturing, covering the entire process from prototype customization to production.

As a well-known factory in the industry, we have passed ISO 9001:2015 and focus on providing plastic and metal prototype services to our customers.

Whether you need one set or over 1000 sets, whether you require engineering grade materials, strict tolerances, complex geometries, or exquisite surface treatments, we are committed to meeting your design and manufacturing needs. Our company mission is to help you turn your ideas into reality.

Why Choose Yigu

Price advantage

Yigu company has a dedicated project quotation team that understands material characteristics, processing techniques, and engineering testing, and provides cost-effective solutions, as well as continuous support and advice from designated sales contacts.

Service excellence

- Business active in -25+countries

- Customers served -3000+

- The professional service of a technical sales team, always paying attention to every detail of your needs.

Rich experience

Supported development projects up to 5000 so far+.

We have a team of professional engineers, mechanics, and skilled craftsmen with over 11 years of experience, which enables us to fully grasp your exact project requirements from prototype to production.

Quality excellent

Tolerance standard:+/-0.0001 ‘to+/-0.0002’

(+/-0.025 millimeters to+/-0.005 millimeters).

30+post-processing procedures.

We have developed an efficient, accurate, and cost-effective process system that can provide excellent results and offer one-stop surface finishing operations to help you tackle your most difficult manufacturing challenges.

Rapid manufacturing

Prototype customization takes 3-7 days, and small-scale production takes 2-5 weeks.

We are a trusted partner who knows how to accurately manufacture parts according to the required specifications and deliver them on time.

Customer Reviews

“Yigu rapid prototyping service saved us weeks in product development. The 3D-printed surgical models were precise, and the CNC-machined components fit perfectly in our device. Highly recommend for medical innovation teams!”

— Dr. Emily, Lead Product Engineer

“We relied on Yigu CNC expertise for our smartphone accessory line as good partner in China suppliers. The tight tolerances and surface finishes exceeded expectations, and their small-batch production flexibility helped us test markets.”

— James, Director of Manufacturing

“From concept models to functional prototypes, their 3D printing and CNC services delivered on time and within budget. The design process was seamless, and technical support was invaluable for our automotive project.”

— Lucas, Senior Design Manager